WARNING

For LIFTING CLAMP

SUPER TOOL brand lifting clamps are energy-saving lifting equipment which have been developed for the purpose of transporting steel materials.

Proper use

Operate lifting clamps after carefully reading and understanding this instruction manual for enhancing efficiency and safety of operation.

Prime efficiency and economy

Advanced functions, reasonableness and versatile applications of finely and carefully designed SUPER TOOL lifting clamps ensure prime efficiency and economy.

Precautions for safe operation

Be sure to read this instruction manual carefully before use.

Mistaken use of lifting clamp may cause a danger such as dropping of load.

Education of “crane safety regulations,” “operation manual for lifting clamp,” “your company’s operation standards,” etc. should be given before actual operation not only to business owners who have purchased clamps but also to their operators to ensure that actual operators have acquired enough knowledge, safety information, and precautions of the clamps.

Safety precautions are divided into two classifications in this manual; “Warning” and “Caution,”.

| Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury. | |

| Indicates a potentially hazardous situation which, if not avoided, could result in medium damage or slight injury, or could result in property damage. |

While only mentioned in ![]() CAUTION, failure to comply with them still may lead to a serious disaster. As such, do not fail to pay attention both to WARNING and CAUTION which are of great importance.

CAUTION, failure to comply with them still may lead to a serious disaster. As such, do not fail to pay attention both to WARNING and CAUTION which are of great importance.

Meanings of Signs

The signs of ![]() and

and ![]() indicate that precautions should be taken.

indicate that precautions should be taken.

The contents of warning or caution are described at each sign.

The sign of ![]() indicates prohibited actions.

indicates prohibited actions.

The sign of ![]() indicates that an action is enforced or instructed.

indicates that an action is enforced or instructed.

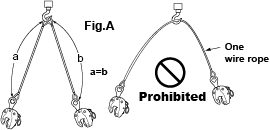

Two point lift for ![]() righthand figure.

righthand figure.

※After reading this manual, make sure to keep it at a place of easy access by any users.

1. Handling in general

|

Prohibited |

|

Instructed |

2. Check before operation

|

Prohibited |

|

Instructed |

|

Prohibited |

|

Instructed |

3. Lifting operation

|

Prohibited |

|

Two point lift |

|

Instructed |

|

Prohibited |

4. Operation of a crane

|

Prohibited |

|

Instructed |

|

Prohibited |

|

Instructed |

5. Maintenance, storage and alteration

|

Prohibited |

|

Instructed |

|

Instructed |

■General warning for use(common to all lifting clamp models)

- Be sure to select proper model clamps for use.

Pay special attentions to keep the lifting direction (rope angle). - Confirm the weight of the load. Do not exceed maximum capacity (designated ton) on clamps. (Never overload.)

- Before use, confirm followings:

(a)Proper capacity of clamps.

(b)No abnormal movements of clamp or loosening of any bolts.

(c)No oil or other foreign matters on the surface of the cam and pad. - Never use for load beyond the clamp range.

- When installing clamps, insert a lifting load completely until it comes in contact with the deepest of the jaw opening of main body.

- Depending on the model or capacity of the clamp, the cam teeth may not bite a load sufficiently when the load is a hard or light weight material (Less than 1/5 of maximum capacity or less than 1/4 of maximum clamp range). Confirm the condition of clamp for safety.

- Confirm that the safety lock is completely engaged in case clamp has a built-in lock.

- Confirm that the load is well balanced. Determine the clamp position or the center of gravity of the rope properly. It is especially important to determine the horizontal center of gravity.

- When lifting at 2 points, be sure to use two wire ropes, and make them equal length. (Fig. A)

- When lifting at 2 points, keep the lifting angle within 60°. (Fig. B)

(Follow the standards if lifting angle is specified depending on items.) If the load is long, use a balance.

- Never lift two or more steel plates or steel members at a time.

- The load may move to an unexpected direction when lifted off the ground and as such confirm the center of gravity and the clamping position for safety when raising. Sufficient caution should be taken until the clamp with the load becomes completely balanced.

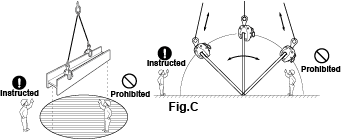

- When changing directions of the load or any similar operations, all personnel must be clear of the area of operation. (Fig. C)

- Do not ride on the lifting load. Never use clamp for riding or carrying person.

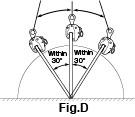

- Keep momentary inverting angle of a steel plate within 30°. (Fig. D)

- Before operation, the surface of load must always be clean and free of scale, coatings or other foreign matters that will reduce clamping force significantly.

- When raising, special attention must be given to prevent the rope from loosening by its unintended contact with any other objects.

- When raising again after the load is put on ground, reconfirm the clamp condition. Be sure to retighten to the specified torque for screw cam clamps.

- Do not use clamp for heated load or in a corrosion liquid because safety factor and durability will be reduced in such conditions.

- Do not alter clamp by welding, cutting by gas or by any other modification.

- Do not weld electrically a load while being lifted by clamp.

- Conduct daily maintenance and lubrication.

■Maintenance and Inspection

1.Maintenance

Daily maintenance is important for efficient and safe operation even under the severe use condition and for such purposes, please comply with the followings.

- Designate the use standards and control.

- Keep clamps indoor and do not leave them outdoor.

- Check the followings to maintain in a good condition.

(a)Operating condition.

(b)Any abrasion, damage, or clogging at teeth of cam and pad.

(c)Deformation of main body - at jaw opening in particular. - Separate conforming clamps and other hazardous items identified during use or inspection and designate the defective sections. Perform maintenance any soon.

- For the storage, place soft material as wooden chip in-between cam and pad to protect the teeth.

- Establish own schedule and perform regular inspection and maintenance by referring to “Inspection Standards”. Lubricate sliding sections periodically. (However, remove oil from the teeth of the cam and pad.)

2.Periodic Inspection

Perform periodic inspection in accordance with the periodic inspection and maintenance standards. Functions and life of clamps may differ in a great degree as they are used in varieties of fields under different conditions of use. Therefore, preparation and practice of effective handling/inspection standards manual by users themselves are recommended. We ask you to establish complete maintenance and control for assurance of safety in reference to our Manufacturer’s Inspection Standards of our clamp. Clamp is designed for easy replacement of parts and therefore, do not fail to replace defective parts. Also, keeping spare parts at all times is recommended. For your preparation of the standards, pay special attention to the followings.

- Operation and maintenance standards

(a)Preparation of use criteria (shape of load and operating methods).

(b)Thorough understanding and compliance of cautions on handling.

(c)Maintenance and storage.

(d)Rules of inspection and check at site. - Standards on periodic inspection

(A)Establishing dates of periodic inspection.

(B)Establishing inspection and maintenance methods.

(a)Inspecting period.

(b)Person in charge of the inspection.

(c)Inspection site.

(d)Tools and devices for inspection.

(e)Establishment of permissible limit of use.

(f)Explicit designation of maintenance and repair methods.

3.Manufacturer’s inspection method

Our company’s inspection procedures are as follow.

Check for

- Movements.

- Wear, loss, and/or clogging of/at the teeth of the cam and screw.

- Deformation of main body.

- Deformation of shackle.

- The status of bolts, pins, links and springs.

- Deep scratches in general.

- Other checking items based on the Standards.

Lifting angle and rated load of wire rope

The maximum rated capacity of wire ropes also differs according to the lifting angle.

Therefore, after paying attention to the lifting angle, always use wire ropes with the appropriate diameter.

Correlation table between the lifting angle and the applicable load for wire rope (for 2-point lifting)

■JIS G 3525 6×24 A type

| D wire rope diameter (mm) |

W rated load (for 1 single rope) 【Safety factor S=6】 (ton) |

|||

|---|---|---|---|---|

| (Change in % of the lifting capacity rate according to the lifting angle) | ||||

| 100% | 96% | 86% | ||

| Maximum allowable load (rated load) for 2 wire ropes (ton) | ||||

| 6 | 0.30 | 0.60 | 0.57 | 0.51 |

| 8 | 0.53 | 1.07 | 1.03 | 0.92 |

| 9 | 0.67 | 1.35 | 1.30 | 1.16 |

| 10 | 0.83 | 1.67 | 1.61 | 1.44 |

| 12 | 1.20 | 2.41 | 2.32 | 2.08 |

| 14 | 1.64 | 3.28 | 3.15 | 2.83 |

| 16 | 2.14 | 4.28 | 4.12 | 3.69 |

| 18 | 2.72 | 5.44 | 5.23 | 4.69 |

| 20 | 3.35 | 6.70 | 6.44 | 5.77 |

| 22 | 4.06 | 8.12 | 7.81 | 7.00 |

| 24 | 4.82 | 9.65 | 9.28 | 8.32 |

| 26 | 5.66 | 11.3 | 10.8 | 9.76 |

| 28 | 6.58 | 13.1 | 12.6 | 11.3 |

| 30 | 7.55 | 15.1 | 14.5 | 13.0 |

| 32 | 8.58 | 17.1 | 16.5 | 14.8 |

| 36 | 10.8 | 21.7 | 20.8 | 18.7 |

| 40 | 13.4 | 26.8 | 25.8 | 23.1 |

Calculation formula of a wire rope diameter and rated load (for 1 single rope)

※Refer to the calculated values as rough indications.

For SUPER LOCK HOOK

SUPER TOOL brand lock hooks are energy-saving lifting equipment which have been developed for the purpose of lifting operations during the laying and removal of steel floor plates or lifting operations using wire ropes, sling belts, etc.

Proper use

Operate lock hooks after carefully reading and understanding this operation manual for enhancing efficiency and safety of operation.

Prime efficiency and economy

Advanced functions, reasonableness and versatile applications of finely and carefully designed SUPER TOOL brand lock hooks ensure prime efficiency and economy.

Special considerations on safety

We conduct a pulling test with a load three times of rated capacity and a manufacturing serial number is marked on each product, thus directing a special attention to safety.

Precautions for safe operation

Be sure to read this instruction manual carefully before use.

Mistaken use of super lock hook may cause a danger such as dropping of load.

Education of “crane safety regulations,” “operation manual for lifting clamp,” “your company’s operation standards,” etc. should be given before actual operation not only to business owners who have purchased clamps but also to their operators to ensure that actual operators have acquired enough knowledge, safety information, and precautions of the clamps.

Safety precautions are divided into two classifications in this manual; “Warning” and “Caution,”.

| Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury. | |

| Indicates a potentially hazardous situation which, if not avoided, could result in medium damage or slight injury, or could result in property damage. |

While only mentioned in ![]() CAUTION, failure to comply with them still may lead to a serious disaster. As such, do not fail to pay attention both to WARNING and CAUTION which are of great importance.

CAUTION, failure to comply with them still may lead to a serious disaster. As such, do not fail to pay attention both to WARNING and CAUTION which are of great importance.

Meanings of Signs

The signs of ![]() and

and ![]() indicate that precautions should be taken.

indicate that precautions should be taken.

The contents of warning or caution are described at each sign.

The sign of ![]() indicates prohibited actions.

indicates prohibited actions.

The sign of ![]() indicates that an action is enforced or instructed.

indicates that an action is enforced or instructed.

Two point lift for ![]() righthand figure.

righthand figure.

※After reading this manual, make sure to keep it at a place of easy access by any users.

1. Handling in general

|

Prohibited |

|

Instructed |

2. Check before operation

|

Prohibited |

|

Instructed |

|

Prohibited |

|

Instructed |

3. Lifting operation

|

Prohibited |

|

Instructed |

|

Prohibited |

4. Operation of a crane

|

Prohibited |

|

Instructed |

|

Prohibited |

|

Instructed |

5. Maintenance, storage and alteration

|

Prohibited |

|

Instructed |

|

Instructed |

■Maintenance and Inspection

1.Maintenance

Daily maintenance is important for efficient and safe operation even under the severe use condition and for such purposes, please comply with the followings.

- Keep lock hook indoor and do not leave them outdoor.

- Check the followings to maintain in a good condition.

(a)Operating condition.

(b)Any abrasion, damage, or clogging at teeth of cam and pad. - Separate conforming lock hook and other hazardous items identified during use or inspection and designate the defective sections.

- Perform maintenance any soon.

- Perform inspection and maintenance once a week by referring to “Inspection Standards”. Lubricate sliding sections periodically

2.Periodic Inspection

Perform periodic inspection in accordance with the periodic inspection and

maintenance standards. Functions and life of lock hook may differ in a great degree as they are used in varieties of fields under different conditions of use. Therefore, preparation and practice of effective handling/inspection standards manual by users themselves are recommended.

We ask you to establish complete maintenance and control for assurance of safety in reference to our Manufacturer’s Inspection Standards of our lock hook. Lock hook is designed for easy replacement of parts and therefore, do not fail to replace defective parts. Also, keeping spare parts at all times is recommended. For your preparation of the standards, pay special attention to the followings.

- Operation and maintenance standards

(a)Preparation of use criteria (shape of load and operating methods).

(b)Thorough understanding and compliance of cautions on handling.

(c)Maintenance and storage.

(d)Rules of inspection and check at site. - Standards on periodic inspection

(A)Establishing dates of periodic inspection.

(B)Establishing inspection and maintenance methods.

(a)Inspecting period.

(b)Person in charge of the inspection.

(c)Inspection site.

(d)Tools and devices for inspection.

(e)Establishment of permissible limit of use.

(f)Explicit designation of maintenance and repair methods.

3.Manufacturer’s inspection method

Our company’s inspection procedures are as follow.

Check for

- Movements.

- Deformation of main body.

- Deformation of shackle.

- The status of bolts, pins, and springs.

- Deep scratches in general.

- Other checking items based on the Standards.

Lifting angle and rated load of wire rope

The maximum rated capacity of wire ropes also differs according to the lifting angle.

Therefore, after paying attention to the lifting angle, always use wire ropes with the appropriate diameter.

Correlation table between the lifting angle and the applicable load for wire rope (for 2-point lifting)

■JIS G 3525 6×24 A type

| D wire rope diameter (mm) |

W rated load (for 1 single rope) 【Safety factor S=6】 (ton) |

|||

|---|---|---|---|---|

| (Change in % of the lifting capacity rate according to the lifting angle) | ||||

| 100% | 96% | 86% | ||

| Maximum allowable load (rated load) for 2 wire ropes (ton) | ||||

| 6 | 0.30 | 0.60 | 0.57 | 0.51 |

| 8 | 0.53 | 1.07 | 1.03 | 0.92 |

| 9 | 0.67 | 1.35 | 1.30 | 1.16 |

| 10 | 0.83 | 1.67 | 1.61 | 1.44 |

| 12 | 1.20 | 2.41 | 2.32 | 2.08 |

| 14 | 1.64 | 3.28 | 3.15 | 2.83 |

| 16 | 2.14 | 4.28 | 4.12 | 3.69 |

| 18 | 2.72 | 5.44 | 5.23 | 4.69 |

| 20 | 3.35 | 6.70 | 6.44 | 5.77 |

| 22 | 4.06 | 8.12 | 7.81 | 7.00 |

| 24 | 4.82 | 9.65 | 9.28 | 8.32 |

| 26 | 5.66 | 11.3 | 10.8 | 9.76 |

| 28 | 6.58 | 13.1 | 12.6 | 11.3 |

| 30 | 7.55 | 15.1 | 14.5 | 13.0 |

| 32 | 8.58 | 17.1 | 16.5 | 14.8 |

| 36 | 10.8 | 21.7 | 20.8 | 18.7 |

| 40 | 13.4 | 26.8 | 25.8 | 23.1 |

Calculation formula of a wire rope diameter and rated load (for 1 single rope)

※Refer to the calculated values as rough indications.